What Commercial Expansion Joint Repair Is—and Why It’s Critical

Commercial expansion joint repair is the process of identifying, restoring, and sealing the vital joints in large concrete structures—like parking garages, high-rises, and commercial slabs—to prevent water infiltration and structural damage. In South Florida’s harsh, humid climate, these repairs keep buildings safe, operational, and free from leaks that cause costly downtime or tenant complaints.

Quick Guide: What You Need to Know

If you manage a commercial property and are worried about joint leaks or cracks:

| Problem | Solution | Downtime | Permanent? |

|---|---|---|---|

| Leaking or cracked joints | Contact CL Wizard for permanent repair | Minimal/none | Yes (guaranteed) |

| Temporary water infiltration | Traditional waterproofing (old method) | Days/Weeks | No (short-lived) |

| DIY caulking/epoxy | Not advised for commercial structures | Varies | No (risk of failure) |

Key facts:

- Expansion joints in concrete allow for safe movement—necessary for South Florida’s temperature swings and rain.

- Neglecting joint repair leads to slab cracking, rebar corrosion, and expensive emergency repairs.

- Only a professional, permanent solution—like the CL Wizard system—stops leaks for good without disrupting daily life.

“Replacing expansion joints is much easier and more cost-effective than replacing entire concrete slabs.”

—Industry Expert

As Marco Aurélio Rocha Sousa Filho, I’ve spent over eight years developing and applying permanent solutions for commercial expansion joint repair throughout Florida’s toughest environments. My specialized experience in concrete and water infiltration means you get lasting results that avoid the pitfalls of traditional repair methods.

Commercial expansion joint repair terms to learn:

Why Expansion Joints Matter in Large Commercial Buildings

Understanding why expansion joints are crucial starts with basic physics. Concrete expands at a rate of 0.0000055 inches per linear inch per 1°F temperature change. This means a 100-foot commercial slab can expand by up to 1.06 inches with a 60°F temperature increase—common in South Florida’s climate where temperatures can swing from air-conditioned interiors to scorching parking garages.

In large commercial buildings like the high-rises we work on throughout Miami, Boca Raton, and West Palm Beach, this thermal movement happens constantly. Without properly functioning expansion joints, the concrete has nowhere to go but crack. Scientific research on concrete expansion confirms that uncontrolled thermal stress is one of the leading causes of structural failure in commercial concrete.

The structural integrity of your building depends on these joints working correctly. When they fail, you’re not just looking at cosmetic issues—you’re facing:

- Safety hazards from uneven surfaces and trip hazards

- Massive downtime costs when emergency repairs shut down parking areas or building access

- Tenant complaints from water infiltration and unsightly damage

- Insurance liability from slip-and-fall incidents

Hidden Risks of Neglected Joints

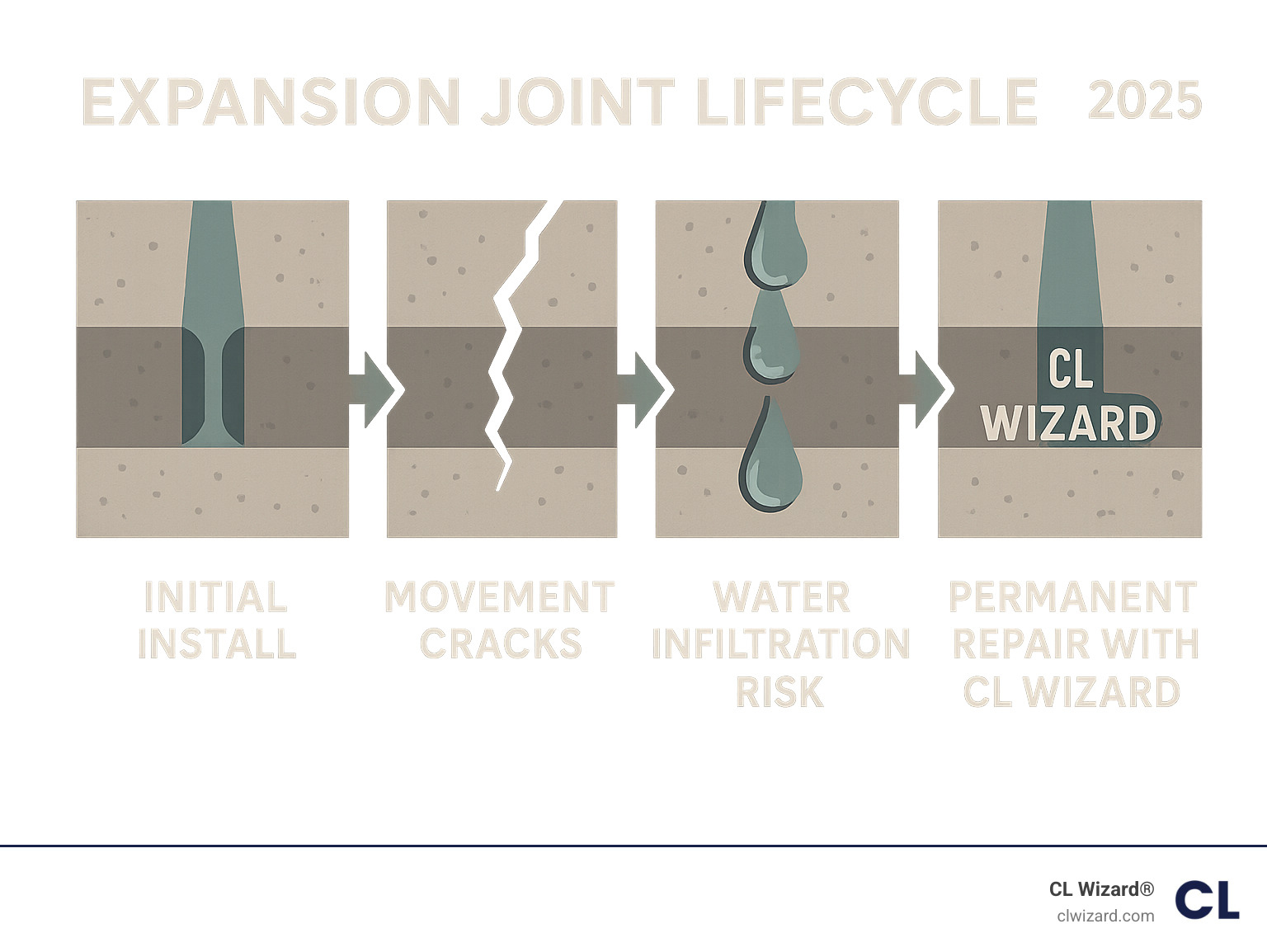

What many property managers don’t realize is that expansion joint failure creates a domino effect of problems. When joints crack or separate, water infiltration leads to concrete spalling—where chunks of concrete literally fall off the structure. This exposes the steel reinforcement bars (rebar) to moisture, causing corrosion that weakens the entire building.

We’ve seen parking garages in Hollywood and Delray Beach where neglected expansion joints created trip hazards so severe that entire sections had to be cordoned off. The cost of emergency repairs, lost parking revenue, and potential lawsuits far exceeds the price of proper preventive maintenance.

Top Solutions for Commercial Expansion Joint Repair

After working on hundreds of commercial properties across South Florida, we’ve evaluated every major repair method available. Here’s our comprehensive breakdown of the most effective solutions for commercial expansion joint repair:

| Solution Type | Service Life | Disruption Level | Permanent Fix | Best For |

|---|---|---|---|---|

| Elastomeric Sealants | 5-10 years | Medium | No | Surface joints |

| Pre-formed Gaskets | 10-15 years | High | No | Replacement projects |

| Epoxy/Polyurea | 10-20 years | High | No | Heavy traffic areas |

| Polyvinyl Injection | 25+ years | None | Yes | All applications |

Elastomeric Sealants for Commercial Expansion Joint Repair

Traditional elastomeric sealants represent the most common approach to expansion joint repair. These self-leveling urethane compounds require careful installation with backer rod at proper depths to control sealant thickness. The industry standard allows for movement of ±25% of the joint width, which sounds adequate but often falls short in South Florida’s extreme temperature variations.

The major limitation we’ve observed is that these sealants require complete joint preparation—saw-cutting, cleaning, and often temporary closure of the repair area. Even with perfect installation, they typically need replacement every 5-10 years as they lose elasticity and begin to crack or pull away from the concrete.

Pre-Formed Gaskets & Inserts

Vinyl extrusions and rubber gaskets offer immediate traffic capability once installed, making them popular for high-traffic areas. These systems also provide excellent weed deterrent properties, which is valuable in outdoor applications like parking lots and walkways.

However, installation requires complete removal of existing joint material and often involves demolition work. The disruption to building operations can be significant, especially in occupied commercial buildings where noise and dust restrictions apply.

Epoxy & Polyurea Systems

Rapid-set epoxy and polyurea systems excel in high-load applications where joints must support heavy traffic immediately after installation. These systems typically cure within 30 minutes to 2 hours, allowing quick return to service.

The downside is the extensive preparation required—saw-cutting, surface grinding, and complete joint cleaning. The chemical odors and safety requirements also make these systems challenging to use in occupied buildings.

Polyvinyl Injection: The Future of Commercial Expansion Joint Repair

This is where the CL Wizard system revolutionizes commercial expansion joint repair. Our proprietary polyvinyl injection method uses a liquid that has the same properties as water, allowing it to penetrate into the smallest cracks and voids within the expansion joint. After a short time, this liquid hardens into a rubber-like substance that permanently fills and seals the joint.

The key advantages of our system include:

- Zero demolition required—no saw-cutting or joint preparation

- No disruption to building operations—people can continue using the space during repairs

- Permanent solution—the polyvinyl material becomes part of the concrete structure

- Superior penetration—reaches areas traditional sealants cannot access

- Immediate results—no curing time or traffic restrictions

We’ve successfully repaired expansion joints in swimming pools while people continued swimming, and in parking garages without closing a single parking space. This level of convenience is impossible with traditional repair methods.

Best Practices for Preparing and Installing Repair Materials

When traditional repair methods are used, proper preparation is critical for long-term success. Surface grinding removes loose concrete and creates a clean bonding surface. Bond-breaker tape prevents three-sided adhesion that can cause sealant failure. Joint-movement calculations ensure the repair can accommodate expected thermal expansion.

Personal protective equipment (PPE) is essential when working with chemical sealants—proper ventilation, eye protection, and chemical-resistant gloves protect workers from harmful exposure.

However, the CL Wizard system eliminates most of these preparation requirements. Our expansion joint leak repairs process requires minimal surface preparation because the polyvinyl material bonds at the molecular level with the existing concrete.

Scheduling Repairs to Minimize Downtime

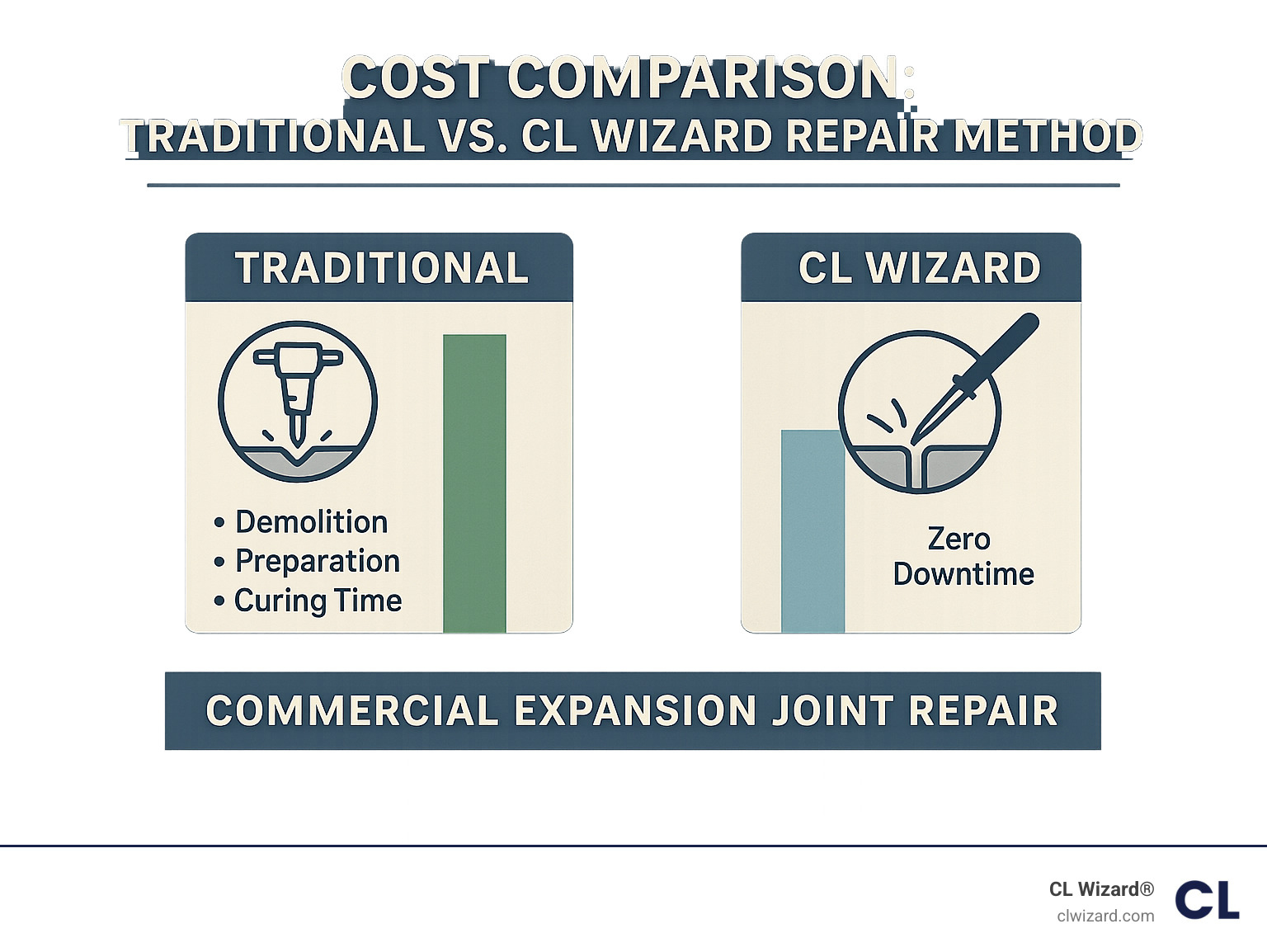

Traditional repair methods often require night work or phased lane closures to minimize disruption. Even with careful planning, most conventional repairs require 30-minute to several-hour closure periods for curing.

Our approach allows repairs during normal business hours without any closure requirements. Property managers can schedule repairs at their convenience without coordinating with tenants or losing revenue from closed parking spaces.

Cost, Risk, and Maintenance Considerations

Preventive budgeting for expansion joint maintenance should account for the total cost of ownership, not just initial repair costs. Traditional methods may seem less expensive upfront, but the recurring maintenance, downtime costs, and eventual replacement make them significantly more expensive over time.

The ROI compared to slab replacement is dramatic. We’ve seen cases where neglected expansion joints led to complete slab failure requiring $50,000+ in emergency repairs. Our permanent solution typically costs a fraction of that amount while eliminating future maintenance needs.

Warranty terms vary significantly between repair methods. Traditional sealants typically offer 1-2 year warranties, while our polyvinyl injection system comes with comprehensive long-term protection.

Annual inspections remain important even with permanent repairs, but the focus shifts from joint maintenance to overall structural monitoring. Our commercial building leak solutions include ongoing support to ensure your building remains leak-free.

Long-Term Benefits of Proper Joint Maintenance

Structural longevity increases dramatically with proper expansion joint maintenance. Buildings with well-maintained joints experience fewer concrete spalling issues, reduced rebar corrosion, and better overall structural integrity.

Insurance savings can be substantial when buildings demonstrate proactive maintenance programs. Many insurance companies offer reduced premiums for buildings with documented preventive maintenance records.

Tenant safety improvements reduce liability exposure and create a more attractive property for lease renewals and new tenants.

Frequently Asked Questions about Commercial Expansion Joint Repair

How do I know my commercial joints need repair?

Look for these warning signs:

- Visible cracks or gaps in joint sealant

- Water stains or active leaks near joints

- Loose or missing joint material

- Uneven surfaces or trip hazards

- Weed growth in joint openings

If you notice any of these issues, contact us immediately. Early intervention prevents minor problems from becoming major structural issues.

Why shouldn’t I attempt a DIY fix on a high-rise?

Commercial expansion joint repair in high-rise buildings requires specialized knowledge of structural engineering, building codes, and safety requirements. DIY repairs often fail because:

- Incorrect material selection for the specific application

- Inadequate surface preparation

- Improper joint sizing and movement calculations

- Safety hazards from working at height

- Liability issues if repairs fail

The risks far outweigh any potential savings. Professional repair ensures proper materials, techniques, and warranty protection.

How does polyvinyl injection outperform traditional sealants?

Traditional sealants sit on top of the joint and rely on adhesion to the concrete surface. Our polyvinyl injection actually penetrates into the concrete structure, creating a permanent bond that becomes part of the building itself.

Key performance differences:

- Penetration depth: Our system reaches areas traditional sealants cannot access

- Flexibility: Polyvinyl maintains rubber-like properties indefinitely

- Durability: No degradation from UV exposure or chemical exposure

- Application: No demolition or surface preparation required

- Permanence: One-time application lasts the life of the building

Conclusion

Commercial expansion joint repair is too important to leave to chance or temporary solutions. In South Florida’s challenging climate, permanent waterproofing solutions are essential for protecting your investment and ensuring tenant safety.

For Miami high-rise owners and commercial property managers throughout South Florida, the CL Wizard solution offers superior performance with zero disruption to your operations. Our proprietary polyvinyl injection system permanently seals expansion joints without demolition, downtime, or recurring maintenance costs.

Don’t let failing expansion joints compromise your building’s structural integrity or create liability issues. Contact CL Wizard today to learn how our permanent solution can protect your property for decades to come.

Get a Quote for your Concrete Water Infiltration Repair

Follow us!